BRI delivers growth and protection amid pandemic

Suppliers, officials work in full swing building a global

A China-Europe freight train containing 294.42 tons of epidemic prevention materials departs from Wuhan, Central China's Hubei Province heading for Belgrade, Serbia in May 2020. Photo: Xinhua

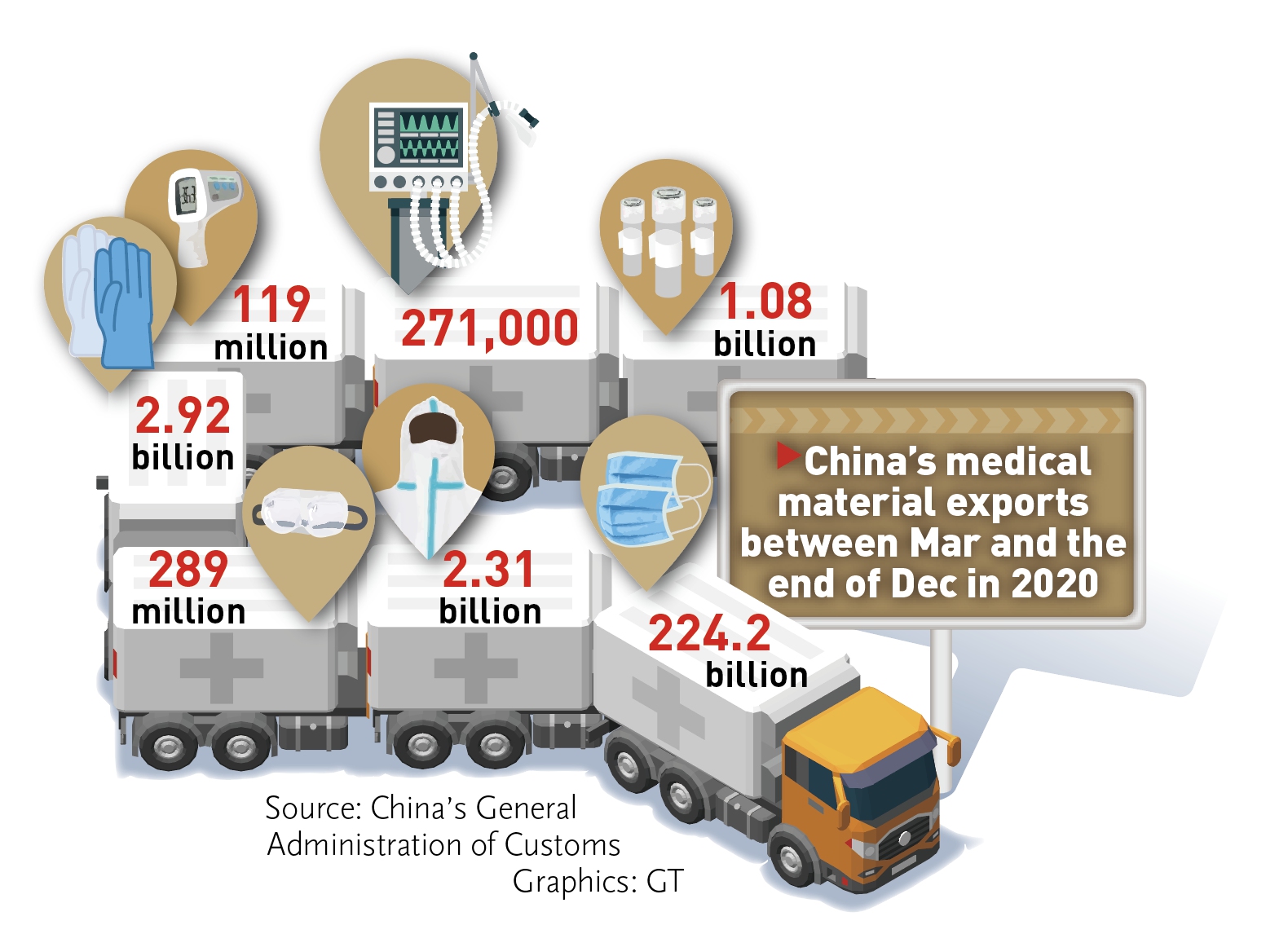

Despite logistic hurdles and global complexity posed by the COVID-19 pandemic, Chinese medical and personal preventive equipment (PPE) to countries and regions along the routes of Belt and Road Initiative (BRI) have been on an upward trend since early last year, another example of China's efforts to support its partners in fighting against the odds.

China's imports and exports to countries and regions along the Belt and Road routes reached 9.37 trillion yuan ($1.45 trillion) in 2020, up 1 percent year-on-year, in which epidemic PPE items accounted for a significant proportion, Chinese customs data showed.

The country's efforts to support epidemic prevention in those countries can be reflected in the operating rate of China-Europe freight train routes. When global shipping was blocked and air freight rates soared, the China-Europe freight train, an important channel connecting with those countries, demonstrated the unique advantages of international railway transport and the importance of "life channel."

In 2020, the China-Europe freight trains delivered a total of 9.39 million pieces of epidemic prevention materials, weighing 76,000 tons.

Behind the resilient exports are the hardworking suppliers and government officials who worked extra shifts against all difficulties to ensure the delivery of the much-needed life-saving equipment to the Belt and Road countries.

Graphics: GT

Robust in complexity

2020 was the year of struggling yet rewarding to many domestic PPE suppliers. When Huang Yuhao, president of Health Box in East China's Anhui Province, a domestic mask producer, reviewed his first "mission-impossible" orders from Hungarian Embassy in Beijing last March, he could still remember how he managed to ensure the 20 million surgical masks, 200,000 surgical protective suits, and 1 million N95 masks being delivered from scratch within 10 days.

"The production schedule was very tight that although the domestic epidemic was easing at that time, the demand for PPE was high and the supply for the relevant raw materials running short," said Huang, noting that the delivery time was so pressing that they had to count the production capacity daily instead of weekly.

"Thanks to the government's support, the 'green channel' was established to accelerate the procedure of production and distribution, eventually enabling delivery on time," said Huang.

Hungary was not the only country along the BRI routes in need of PPE. As more and more countries reported the epidemic, Huang has been on a busy schedule to deliver medical supplies to wider regions ranging from Italy in the West to Singapore and Indonesia in the Southeast Asia.

Huang was certainly not alone in the big group of Chinese suppliers who were fighting against odds. For a long time, the material shortage, high logistic costs and quality issue have all posed hurdles to domestic suppliers' exports.

Zhao Hengchao, a director of port customs at Yiwu West Train Station in East China's Zhejiang Province, who has been in the position for many years, felt that 2020 has been a particularly challenging year for him and his colleagues amid the global pandemic.

As an important hub between China and the European countries along the BRI routes, the port saw the China-Europe freight train trips up nearly 105 percent year-on-year in 2020, with the first half of the year seeing doubled volume, another demonstration of the resilience of the BRI progress despite coronavirus-caused headwinds.

"Since the COVID-19 outbreak, around 120 trains were dispatched per month from Yiwu to Europe, which means 3-4 trains per day on average," said Zhao.

Zhao's home was just 20 minutes away from the port where he worked, but during April to May, the busiest time of the exports, he had to stay over at the office sometimes for a week to get the PPE items loaded on the train on time.

The biggest pressure, however, came with the PPE quality and certificate inspection.

"There were some periods when some Western countries claimed that Chinese masks had quality issue, and in order to be responsible for the reputation of domestic companies and not giving foreign countries any excuse to find fault, we are inspecting goods upon its arrival even at night," said Zhao.

At that time, the mask inspection ratio was very high, and there was a period of 100 percent inspection on every single piece of exports.

"We checked a dozen containers a day. Among a total of 150 million masks that we checked, not a single case of substandard goods for the epidemic prevention has been found," said Zhao.

Despite the difficulties, Zhao and his team saw very satisfying results.

In face of the impact of the epidemic, as a Belt and Road life channel, China-Europe freight trains surpassed the milestone of having 10,000 trains dispatched in 2020, for the first time since its launch, which is 7.3 times the operating volume of 2016, media reports.

In addition to PPE, vaccines have come to play their role in the fighting of COVID-19. To support the world epidemic control, China's novel coronavirus vaccine will serve as a global public good and contribute to the accessibility and affordability of vaccines in developing countries after it is developed and put into use, Zheng Zhongwei, director of the Development Center for Medical Science & Technology of the National Health Commission, said at a media briefing in January.

At present, the first batch of vaccine assistance provided by the Chinese government has been delivered to Pakistan. China is also providing vaccine assistance to 13 developing countries, according to media reports. More than 40 countries have requested vaccine support from China to date.

The global vaccination drives up the demand for syringe. Since last December, more than 20 million milliliter syringes by Zhejiang KangKang Medical Devices Co, a large syringe maker based in Zhejiang, have been exported through foreign traders to Germany, Italy, Spain and other countries.

"Due to the current capacity cannot meet the demand, we can only balance the distribution in between to alleviate the urgent needs of each client," Guo Chun, an executive at Zhejiang KangKang Medical Devices Co, told the Global Times, noting the current order volume continues to increase by several times.

Currently, the company is building a China-Africa medical science and technology industrial park. The facility's first phase of mass production will be put into operation in late April and its planned annual output is forecast to be more than 1 billion syringes, serving the BRI countries and beyond, said Guo.

To ensure the vaccine supplies, a source within Sinovac Biotech surnamed Liu told the Global Times that they are ready for around-the-clock three-shift production throughout the upcoming Lunar New Year.

"Currently, we are expanding a second production line, which has been completed and are expected to put into production in February - the annual production of the vaccine will then exceed 1 billion doses," said Liu.

To meet the urgent need of epidemic prevention and control, Huang's mask enterprises are also working overtime.

Huang's family is in Shanghai and his factory in Anhui, but this year he and his colleagues have to stay put during the holiday to make sure the production is on track.

Last year, Health Box exported around 400-million-yuan protective items to the European countries along the BRI routes, and the figure is expected to double this year.