COMMENTS / EXPERT ASSESSMENT

Americans see dwindling cars on dealer lots; trade war must stop

Illustration: Chen Xia/GT

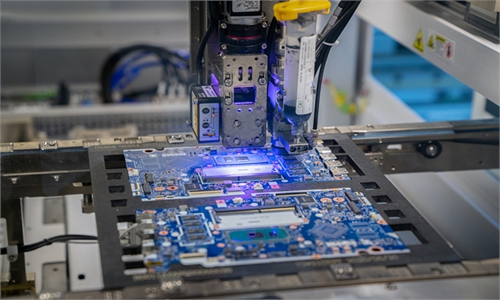

The global crunch of semiconductor microchips is being aggravated, for the automaking industry in particular, so much so that leading car-makers around the world are being forced to idle some of their plants and furlough their workers. The problem is unlikely to be resolved anytime soon and may last as long as 18 months, some industry analysts have claimed, which could impact the livelihoods of millions of people.In the United States, President Joe Biden is personally involved in launching an initiative to ramp up the US chip manufacturing capacity at home so as to protect American manufacturing jobs and enhance his popularity among ordinary American voters. However, it will take at least a cycle of two to three years for a new semiconductor foundry to churn out assembled quality chips.

It will be much better to cooperate with the world's top manufacturing powers, like China, to ensure a speedier recovery of the world's chip supply chain.

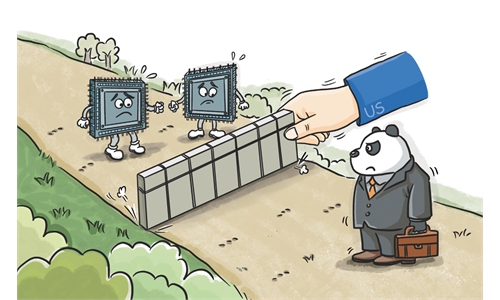

Former US President Donald Trump's reckless trade and technology war with China is one of the crucial culprits behind the current chip crunch. The Trump administration barred China - the world's top chips producer - from obtaining advanced semiconductor manufacturing gear and technology, while making it more difficult to sell Chinese-made products to companies with US ties. That administration placed dozens of Chinese high-tech corporations, such as SMIC and Huawei, on a trade blacklist that helped worsen the global chips production drought.

It is therefore imperative for the Biden administration to reconsider Trump's trade war strategy to contain China's economic development, for pursuing protectionism always backfires and hamstrings oneself in the end. Now, many American autoworkers are losing their jobs while American consumers face the pinch of rising car prices - contributing to the US' latest rise of inflationary pressure.

It is high time for US President Biden and his government to upend the trade war, stop seeking technology "decoupling" with China, and return to the previous roadmap of smooth economic cooperation with China - so that both nations and the world's other economies will benefit from this cooperation.

Otherwise, further industrial sectors will be disrupted and will harm Biden's plan to rejuvenate the US economy, shortly. Any hesitance or inertia not to act by the White House will prolong the harm to both economies, and ultimately harm US post-pandemic recovery and Biden's re-election chance in three years.

Besides the US-China trade war, the coronavirus pandemic is another major factor causing a severe displacement of different kinds of consumer-use semiconductor chips. Last year's lockdowns, remote working and home tutoring for students led families to snap up laptops, smart phones and gaming consoles, which accelerated market demand for the semiconductors needed for manufacturing these electronic devices.

Entering 2021, aided by quick vaccination drives around the world, people are returning to workplaces and they have embarked on another shopping spree - sedans, pickup trucks and SUVs. The average car has between 50 and 200 chips, supporting all types of auto features, such as controlling the automatic braking system, managing the emergency airbag protection system, guiding the driver assistance and navigation system, and increasingly, the chips are the heart of the inner-car infotainment system.

The scarcity of chips has forced global automaking giants to slash production or idle their assembly lines. General Motors (GM) has shut down three of its plants in the US, Canada and Mexico, Volkswagen's factories in Germany and Slovakia were temporarily closed. Mercedes-Benz also halted production at its two plants in Germany at the beginning of this month.

Other auto giants, including Jaguar Land Rover, Renault, BMW Mini, and Stellantis, the French-Italian-American carmaker whose brands include Peugeot, Fiat and Chrysler, have also restricted their output of vehicles.

Leading automakers are now warning of diminished earnings in 2021 due to the chip shortage. Ford said that it has to reduce second-quarter car production in half, and Elon Musk of Tesla warned that the microchips shortage will probably linger through the third quarter this year.

The shortage is now going from bad to worse, spreading from vehicles to consumer electronics. Apple's chief financial officer Luca Maestri recently said that the company expects revenues to be $3 billion to $4 billion lower in the second quarter thanks to semiconductor supply constraints, which affect the production of iPads and iMacs.

In the US market, American consumers see precipitously fewer vehicles on dealer lots, while the prices of new cars, used cars and car rental services have all gone up by more than 20 percent, if compared to 2020 levels, which contributed to approximately one quarter of the hefty 4.2 percent CPI rise or US inflationary rate in April.

Global market watchers say it will take longer than previously forecasted for chip supply and demand to be rebalanced. Some industry experts estimate the crunch will last through this year, and may extend to the second half of 2022.

The semiconductor supply shortage has highlighted the disrupting effect of the highly damaging trade war launched by the former Trump administration, on a supply chain that is truly globalized. Man-made disruption to an important industrial line, causing many factories to close doors, auto workers to lose jobs, car prices to soar, and the scarcity of vehicles on dealer lots in America is deplorable, which ought to be stopped sooner rather than later.

The author is an editor with the Global Times. bizopinion@globaltimes.com.cn