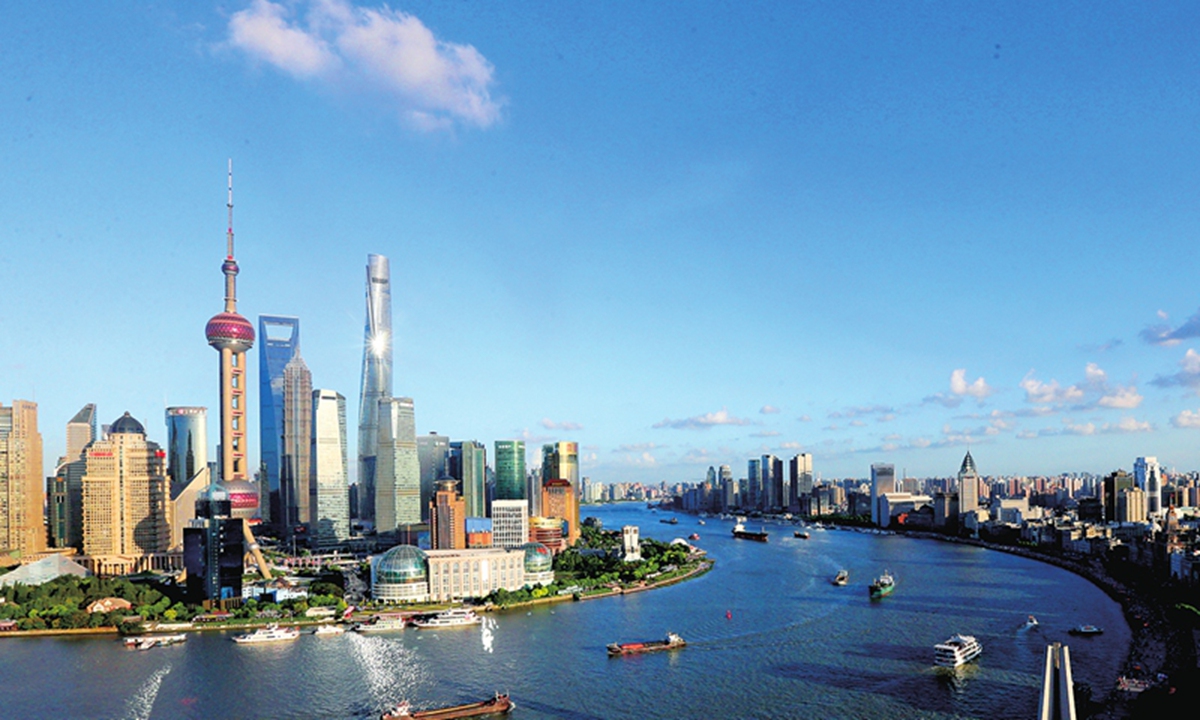

File photo shows a view of the Lujiazui area in Shanghai.Photo:Xinhua

As Shanghai appears set to reduce the negative impact of its coronavirus lockdown on local manufacturing, another factor that is very important to resumption of industrial production is ensuring viability of logistics.The Shanghai Municipal Commission of Economy and Informatization on Saturday issued the first edition of epidemic prevention and control guidelines for the city's industrial enterprises to resume production. According to the policy guidelines, relevant authorities will actively support factories to resume operations, while the enterprises are required to formulate their strict closed-loop management plans.

As a result, local media reported that major Shanghai-based manufacturers, such as Tesla and SAIC Motor, will resume factory production from Monday. The move came at a time when the so-called "static management" or lockdown of the city's social and economic activities has lasted into the third week.

The fact that the manufacturers are allowed to resume production under the closed-loop management model does not mean that Shanghai's fight against the highly contagious Omicron variant is over. The city on Sunday reported 3,238 confirmed and 21,582 asymptomatic domestically transmitted coronavirus cases, marking the 10th consecutive day that the city's daily cases to hover over 20,000.

In China, it is rare to see a city so eager to encourage its factories to resume production when the daily number of new infections remains elevated. However, the peculiar importance of Shanghai in China's overall economic set-up determines that the city of 25 million needs to explore an innovational way to restart factory manufacturing, and do the city's best to contain the epidemic from spreading.

Shanghai, an engine of Chinese economy, is home to the most high-tech manufacturers in the country, including plants of semiconductor chips, auto-making, electronics, chemicals, batteries, and pharmaceuticals. Therefore, if factories in Shanghai shut down for too long, it may trigger disruptions to the entire industrial chains and supply chains, with negative economic implications far and wide.

However, it should be noted that although Shanghai may have the best economic and healthcare conditions to explore a new model that could strike a balance between epidemic prevention and safe resumption of manufacturing activity, nationwide logistics support is indispensable for Shanghai's factories to operate normally.

Over the past several decades, China's logistics sector has been known for its fast development. But due to the sporadic resurgences of the virus in the country, the sector has also encountered growing difficulties.

For instance, Bettina Schoen-Behanzin, chair of the European Chamber of Commerce's Shanghai chapter, said in early April that anti-virus measures were preventing lorry drivers going to areas neighboring Shanghai to pick up cargo have created a "black hole" in the logistics chain, which is of vital importance to multinational manufacturing businesses operating in China.

For any manufacturers planning to resume work in Shanghai, if they cannot have access to quick supplies of upstream components and raw materials, simply gathering workers in the factory area won't be enough for them to return to operational normalcy.

The central government has seen the seriousness of the current logistics problem and moved to promote an orderly recovery of the logistics industry nationwide. The recent news about how JD.com is sending couriers to Shanghai shows that China's logistics industry still has a strong ability to withstand pressure. So it can be expected that the recovery of the logistics sector will accelerate promptly, which will greatly facilitate the restart of manufacturing activity in Shanghai, and elsewhere in China.