Editor's Note:Large models, robots, intelligent manufacturing, autonomous driving... In recent years, artificial intelligence (AI) has frequently made headlines around the world.

In real life, AI has permeated all aspects of human society, helping with scientific research in laboratories, assisting in the restoration of mysterious ancient scrolls at archaeological sites, and helping to find abducted children in the vast sea of humanity. The development of this technology has also brought challenges in various aspects such as in ethics and law. Many experts advocate that humans should see this technology as a tool created for the ultimate purpose of serving humanity, making life and work more efficient and comfortable.

In light of this, the Global Times has launched the "AI empowers industry, improves people's livelihoods" series, showcasing the tremendous energy and broad prospects that AI brings across every aspect of society.

This is the fifth installment in this series. It demonstrates how AI technologies and products empower mines in Northwest China's Xinjiang Uygur Autonomous Region -one of the regions with the most abundant mineral resources in China-largely improving working efficiency and enhancing the protection and safety of workers in these places.

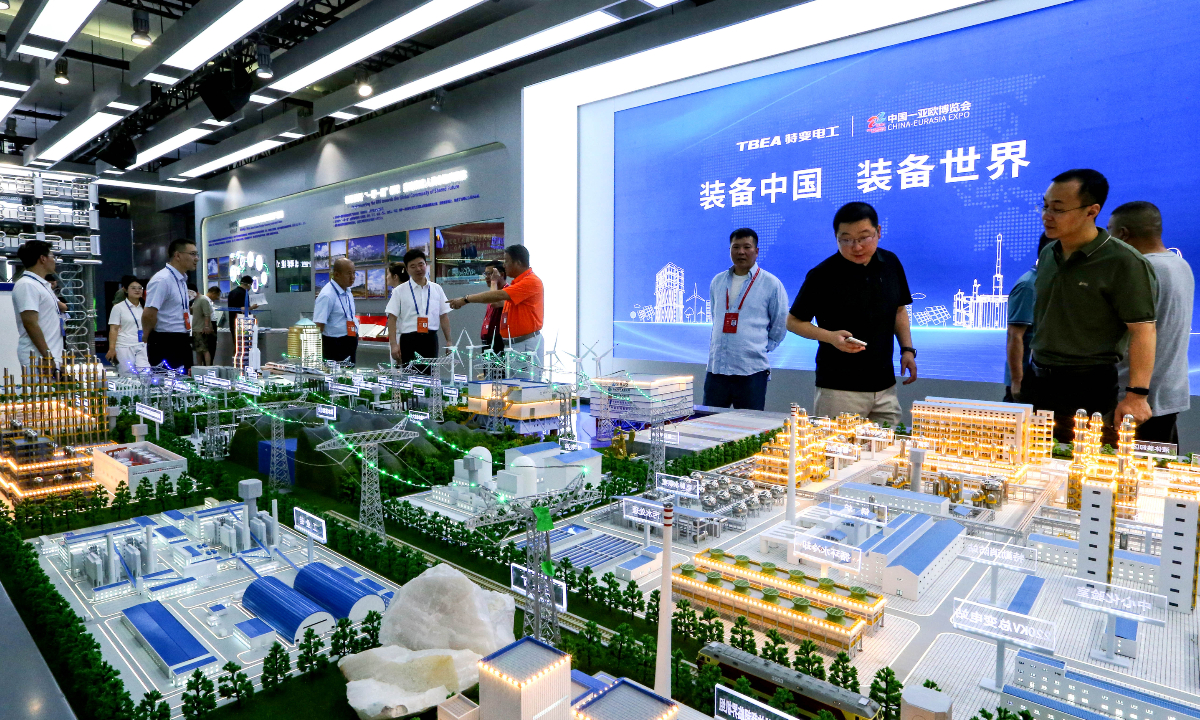

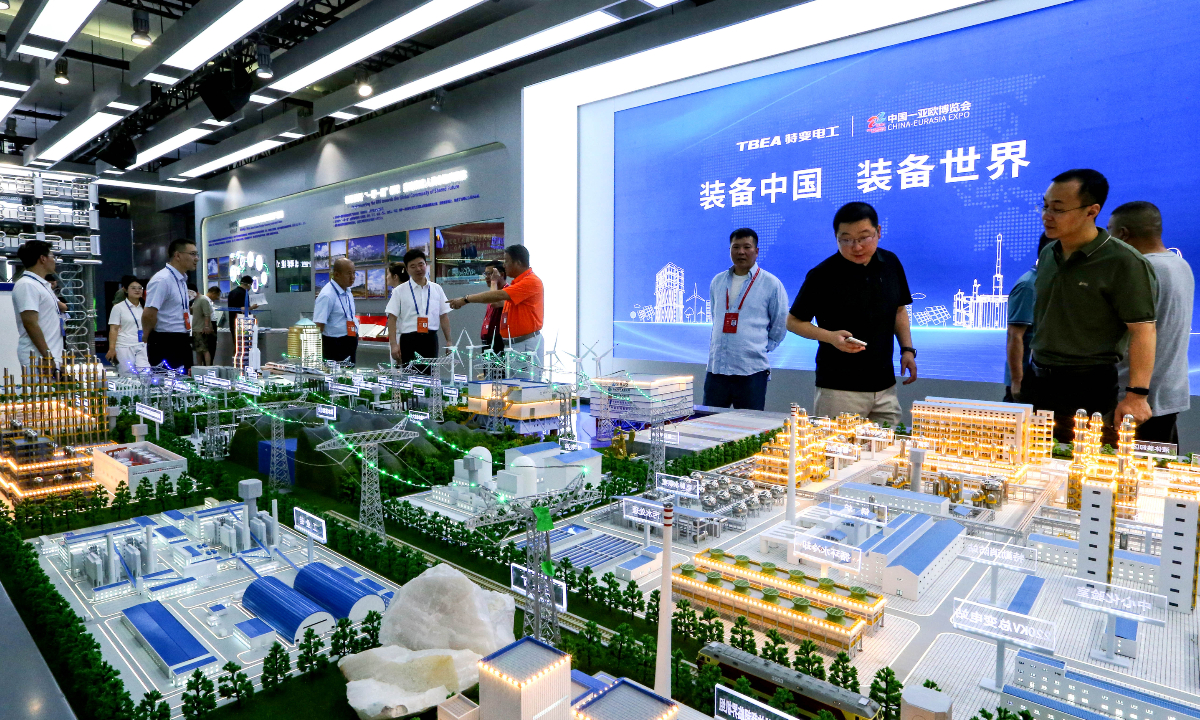

Visitors watch an intelligent mine model of the TBEA displayed at the Xinjiang International Convention and Exhibition Center during the 8th China-Eurasia Expo in Urumqi, Northwest China's Xinjiang Uygur Autonomous Region, on June 27, 2024. Photo: VCG

On a normal working day, Ding Changliang, a maintenance worker at the Xukuang Group Tianshan Mining Company in Xinjiang, saw his cellphone screen suddenly flash a hazard alert, which read that one place in the coal belt had dust accumulation and gave instructions for workers to go to the specific area to clear it.

Upon receiving the alert, Ding quickly rushed to the site to address the issue, taking photos and uploading them to the control platform. After the system recognized and analyzed that the site had meet standard requirements after adjustment, it prompted that the closed-loop process was completed.

"In the past, when there were some on-site issues, we needed to investigate and report first, then dealt with the issue and investigated the site again, which was inefficient. But now, through an intelligent warning platform, risk information is automatically pushed to our phones when we arrive at a work area. We just need to rectify it according to standards, take photos, and upload them to complete the process, which is simple and efficient," Ding said.

With an investment of over 3 millionyuan ($413,000), the Tianshan company has established Xinjiang's first "control and disaster warning platform." The system established creates a risk database for mine water, fire, gas, and roof hazards. It utilizes underground sensors to establish warning rules and risk thresholds, effectively capturing various risks in both time and space to generate real-time data.

When a warning threshold is met, the system triggers alerts through AI video analysis in real-time, automatically notifying technical staff and supervisors of relevant units with details on the time, location, and current parameters. This enables visualization of risk data, precise identification of risk locations, and immediate risk warnings, ultimately bolstering safety risk prevention and control capabilities and elevating accident prevention measures.

Smart 'eyes' The Xukuang Group Tianshan Mining Company is located 69 kilometers north of Kuqa county in Xinjiang's Aksu Prefecture. It operates a coal field 100 kilometers away from Kuqa and the coal field stretches for 8.63 kilometers in length and covers an area of 33.05 square kilometers, with an economically recoverable reserve of 502 million tons, making it the largest contiguous coal field in southern Xinjiang.

In recent years, as Xinjiang region has gotten into the full swing of promoting green mine construction, the Xukang company took active measures to create a model of safe, efficient, intensive, and green intelligent mines.

The Global Times learned from the company that it has collaborated with China Mobile and Huawei, among other companies, to become one of the first in the region to establish a 5G base station. Currently, the company has fully deployed a 5G network underground, enabling intelligent operations and equipping the mines with smart "eyes." Workers on the surface can now control mining equipment hundreds of meters below ground, providing a powerful "smart engine" for the high-quality development of the mines.

"Please confirm whether the equipment status at all positions is normal." "Everything is normal underground, and we are ready for remote startup. Authorization for the 'one-click start' can now be granted." At the company's intelligent dispatch command center, operator Cheng Peng was seen preparing to remotely start the coal mining machine.

This has become a normal scene now in mining operation. According to the company, it has introduced intelligent training equipment for special work types such as mining electric clamp workers, gas inspection workers, coal mining machine drivers, tunneling machine drivers, and main hoist drivers. This training equipment allows for practical demonstrations, hands-on practice, and operational exams, enabling employees to receive high-quality training without leaving the mine.

"Building a smart mine relies on talent, cultivating a group of skilled industrial workers who understand principles, and can operate and can maintain equipment. Our training not only enhances the safety operation skills and professional qualities of employees, but also cultivates a workforce that is learning-oriented, knowledgeable, skilled, and innovative, providing a strong driving force for the high-quality development of intelligent mines," said Yang Ziqiang, director of the company's training center.

Under the requirements to achieve China's "dual carbon" goals - namely reaching peak carbon emissions by 2030 and carbon neutrality by 2060 and high-quality development strategy, more and more mines in Xinjiang are being fitted with "intelligent brains," making working at mines safer and cost effective.

"My father worked in the mine for a lifetime. He could never have imagined that now workers don't have to go down the mine and can remotely control the coal mining," Maimaitiaili Ruzi, deputy director of Wudong Coal Mine under the Xinjiang branch of China Energy, told Xinjiang Daily.

In Maimaiaiti's memories, miners always had coal dust all over their faces. But since he himself entered the mining industry in 1994, he has witnessed an ultimate change of Xinjiang coal mining production from mechanization to being more intelligent.

Picture shows an unmanned vehicle fleet of the open pit coal mine of Tianchi Energy in Jimsar, Xinjiang. Photo: Courtesy of EACON

Intelligent industry

According to the Xinjiang regional government, there are 74 operating coal mines in the autonomous region, including 24 open-pit mines and 50 underground mines. With 28 of local mines having been designated intelligent mines, the region has preliminary formed a smart coal mine production capacity of 169 million tons.

Transforming mines to be more intelligent includes not only the transformation of control systems of the mines, but also that of the equipment for miners.

In an open pit coal mine operated by Tianchi Energy, a subsidiary of Chinese large-scale energy equipment manufacturer TBEA (Tebian Electric Apparatus) Co, Ltd, in Jimsar, Changji Hui Autonomous Prefecture, Xinjiang, 203 unmanned mining trucks are operating 24/7 in an orderly manner to transport soil and rocks. This is the largest unmanned vehicle fleet in a single mine globally.

Based on the precise coordination of Zhushan, autonomous driving solutions for open-pit mines developed by Chinese autonomous haulage solution company EACON, the mine has completed the normalization of unmanned transportation for 50 percent of its topsoil stripping for nearly 20 months, setting an industry benchmark for the large-scale operation of unmanned driving in mines, the Global Times learned from EACON.

Liu Fuming, director of the mine, said that the 303 unmanned vehicles only need six operators. "Every morning the operators will formulate corresponding production plans for each excavator, make appropriate job site planning, and these unmanned mine trucks will work with the excavators without the need for further intervention."

According to Lin Qiao, EACON's vice president, a total of 500 vehicles developed by the company had been operating safely and efficiently in teh whole Xinjiang region for 6 years, accounting for more than 65 percent of all the unmanned vehicles operating in the region.

In early July, staff from EACON attended the World AI Conference (WAIC) in Shanghai for the first time and launched Zhushan 2.0 and its new energy unmanned mining trucks.

"AI has played an important role in driving the intelligent transformation of the mining industry. Based on AI technologies such as deep learning and machine vision, Zhushan 2.0 has achieved precise perception, intelligent decision-making, and efficient operation of mines, and has entered the stage of large-scale replication applications. EACON looks forward to working with more partners to promote the application of artificial intelligence in the field of unmanned driving in mines, and to promote the intelligent upgrade of the mining industry," Lin said.

The company said that it is expected that, by the end of 2024, 1,000 of its unmanned mining trucks would be put into operation, further promoting the large-scale replication of unmanned mining in China. Now the trucks have In the future, hydrogen fueled vehicle models will also be developed to match a wider range of energy systems and scene requirements.

There has been a clear shift in the market's attitude toward unmanned mining enterprises, from questioning and hesitating to resolute approval. Now, the demand for orders can increase by dozens every week. The number of 1,000 is an inevitable goal, Lin said.

Unmanned mining trucks operate in an open pit coal mine operated by Tianchi Energy, a subsidiary of Chinese large-scale energy equipment manufacturer TBEA, in Jimsar, Changji Hui Autonomous Prefecture, Xinjiang. Photos: Courtesy of EACON

Win-win move Xinjiang has set a goal that all coal mines in the region will at least reach the level of primary intelligence by 2025. Industry observers estimate that the intelligent construction and renovation of all 74 coal mines in the region will attract investments of over 10 billion yuan, according to news portal youth.cn.

Along with the development of AI technologies and products in recent years, Xinjiang's promotion of the high quality development of intelligent mining is also expected to benefit neighboring countries, observers said.

From July 18 to 20, the 2024 Silk Road Mining Cooperation Forum and the 14th China Xinjiang International Mining and Equipment Expo was held in Urumqi. The exhibition attracted more than 860 geological, mineral, and oil and gas companies from 26 provinces, regions, and cities across the country, as well as more than 10 countries including Germany and the US, with a total of over 30,000 participants.

Nearly 20 contracts valued at more than 9.6 billion yuan were signed during the exhibition. Iran made its first appearance at this year's exhibition to promote oil and gas exploration and development projects, and the National Mining and Metallurgical Joint Group of Uzbekistan reached cooperation intentions with more than 20 companies, the reports said.

Located in the core area of the Eurasian continent, Xinjiang region is a major gateway connecting Central Asia, with 16 of the 32 confirmed mineral belts in Central Asia involving Xinjiang. The region is one of the important mining areas in China and even globally. Under the framework of the Belt and Road Initiative, the development potential of mineral resources in Xinjiang as well as the whole Central Asia is huge.

Thanks to the country's actions in the past years to boost development of China's western region, Xinjiang has constructed a number of international passage projects. By constructing and utilizing these land passages, neighboring countries will be integrated into Xinjiang and the country's globalized system for mineral resources development and utilization, actively exploring both domestic and international markets and resources.

This will not only provide a broader strategic space for the development of mineral resources in Xinjiang, but also play a special role in building the country's resource and energy security system, observers noted.