Illustration: Chen Xia/GT

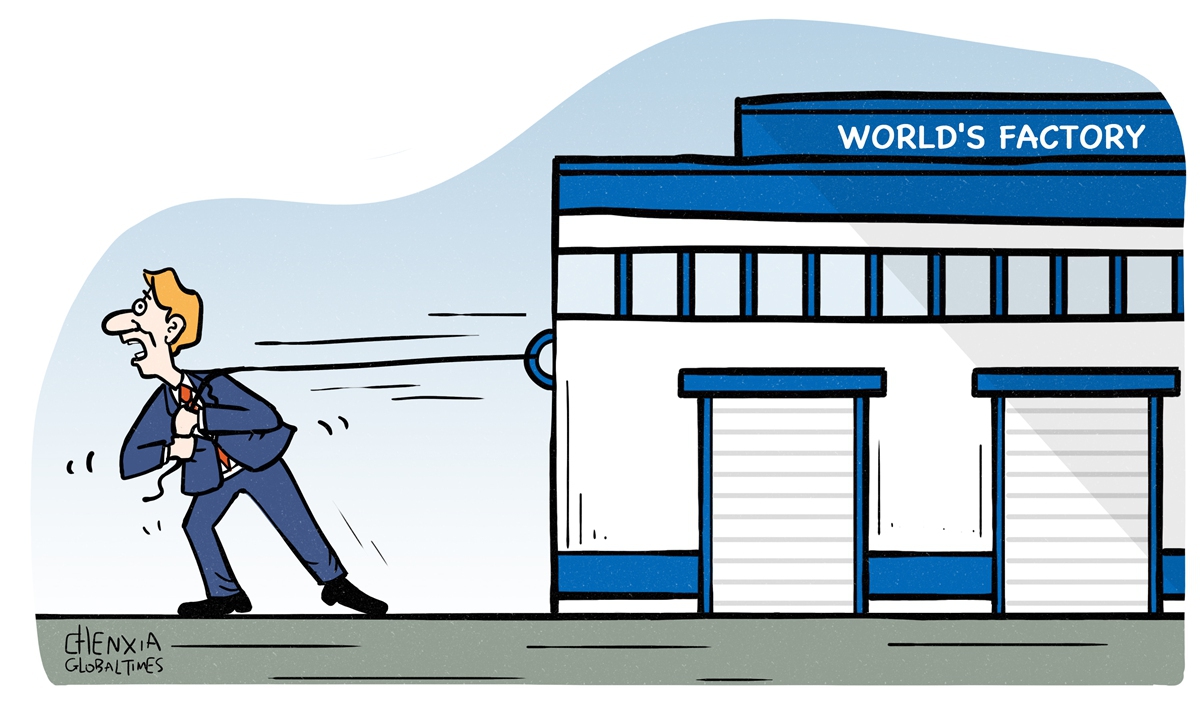

Despite Washington's efforts to relocate manufacturing industrial chains from China to India and some other Asian countries through coercion and inducement, challenges in implementation have revealed that the process is more complicated and thornier than anticipated.Compared with China, the biggest problem with countries that are seen as China's manufacturing substitutes by the US and Europe is social stability. China can be the world's factory because of its national policies and labor force levels. What's more, its stable work and social environment cannot be replaced.

Foxconn announced last week that it had signed a strategic cooperation agreement with the government of Central China's Henan Province, to invest about 1 billion yuan ($137.4 million) in the city of Zhengzhou.

Additionally, due to problems that arose during the assembly of the iPhone 15 in India, Apple has reportedly moved part of its production back to China.

As globally renowned giants, Apple and Foxconn both have strong representative and demonstration effects in the world industrial chain. Their production arrangements and adjustments showcase their responsiveness to the market environment and production conditions, and also underscore China's indispensable role in the global manufacturing industry.

The challenges encountered by other countries attempting to undertake industrial chain transfers reflect the complex nature of global industrial chain restructuring. While the US strategy may initially drive industrial shifts, the ultimate success of such endeavors hinges on a multitude of market forces and economic factors.

In recent years, under the pressure of supply chain diversification and geopolitical factors fueled by the US, some labor-intensive industries in China started moving to countries with cheaper labor. India, Vietnam, and other Southeast Asian and South Asian nations emerged as preferred choices. But the shift hasn't been without difficulties and uncertainties. Many transfers encountered problems, one of the most important of which is political instability.

Some countries may experience political turmoil or social unrest, directly affecting the production of businesses and potentially resulting in property damage and disruptions to supply chains. For instance, the textile industry in Bangladesh has seen a significant influx of foreign investment in recent years, but the recent social unrest and imposition of curfews resulted in substantial losses for businesses. Frequent policy changes and opaque legal environments in some countries also expose foreign manufacturers to greater uncertainty and potential risks.

The cost of labor is another critical factor. Although some countries may have seemingly lower labor costs than China, they have various weaknesses in terms of infrastructure, logistics, industrial support and technical expertise, resulting in lower labor productivity and unreliable supply chains. This may lead to overall costs that even exceed those in China.

The diversification of global demand also matters. Given ever-evolving consumer preferences, businesses need to be able to adapt swiftly to market changes and engage in flexible production. China stands out due to its distinct advantages - a vast domestic market, a well-established supply chain and efficient logistics to meet the diverse needs of companies.

More importantly, there is no easy substitute for China's indispensable role in the global supply chain. China has well-developed industrial infrastructure, mature supply chain systems, skilled technical workers and an efficient logistics network. The integrity of its industrial chain elevates the competitiveness of businesses by improving production efficiency and reducing costs. These unique advantages are hard for other nations to obtain in the short term.

Therefore, some companies that tried to move their operations out of China are opting to return. This decision highlights the resilience of Chinese manufacturing and indicates the need to reassess the decision-making behind global industrial chain strategies among multinationals.

While political considerations may affect companies in the short term, the distribution of industrial chains must ultimately adhere to market principles to ensure optimal resource allocation and long-term profitability for businesses.