Steel coils File photo: Xinhua

China's steel exports periodically capture the attention of the Western public. While Chinese steel exports to Europe and the US remain limited, Western narratives often emphasize external factors as the primary contributors to their companies' challenges. This perspective may inadvertently distract from the critical and urgent efforts that are truly necessary to address the underlying issues facing the industry.European steelmakers have appealed to trade officials to tackle a surge in Chinese steel exports that has driven European prices below the cost of production, the Financial Times reported on Monday.

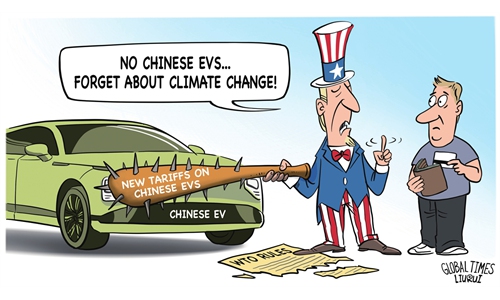

At a time when China and the EU are still engaged in negotiations regarding electric vehicles (EVs), this unexpected move by European steel manufacturers took the market by surprise, sparking concerns about potential shifts in trade measures.

While it is undeniable that Chinese steel exports have a significant impact on global pricing and supply chains, the assertion that the rise in Chinese steel exports has contributed to a decline in European steel prices fails to take into account the complex and multifaceted challenges facing the European steel industry itself.

Despite an increase in China's steel exports this year, Southeast Asia and the Middle East remain the primary markets for Chinese steel products. Chinese exports of steel to Europe constitute only a minor fraction of the country's overall steel exports by volume.

In 2023, China's steel exports to the EU reached 3.66 million tons, accounting for 4 percent of China's total steel exports, according to data from a report by Chinese industry website mysteel.com in May.

The challenges confronting the European steel industry are not solely attributable to external competition; rather, they stem from a complex interplay of internal and external factors.

High production costs in Europe arise from a reliance on imported raw materials, elevated energy and labor expenses, and stringent environmental and carbon emission regulations. These elements collectively undermine the cost competitiveness of European steel products in the global marketplace.

Even in the absence of Chinese exports, steel from other regions would readily fill any market void, further complicating the landscape for European producers. Additionally, the downstream manufacturing sector in Europe would face heightened challenges due to the instability of steel raw material supply, which is critical for a wide array of manufacturing processes.

Since steel is an important raw material for the broader manufacturing sector, keeping European steel prices above global levels will only lead to a loss of international competitiveness for more manufacturing industries in Europe. The future of European steel manufacturing lies in high value-added production, rather than in producing basic commodities in a competitive global market.

The future of the European steel industry hinges on innovation and enhancing product quality to sustain its competitive edge in the high-end market. In recent years, European steel companies have made significant investments and engaged in research and development focused on green technologies, aiming to minimize carbon emissions and resource consumption during production.

These efforts have positioned European steel products well above environmental standards compared with other regions, effectively meeting the rising global demand for high-quality, low-carbon solutions. Moreover, a portion of China's specialty steel imports continues to come primarily from Europe, South Korea and Japan.

Despite the competition, the steel industries of China and Europe also collaborate on various projects. For instance, during the 6th China International Import Expo, China Baowu Steel Group signed procurement contracts with several European companies involving production line equipment and some raw materials. These collaborative projects enhance the quality of Chinese steel products and provide growth opportunities for the European steel sector, creating mutually beneficial opportunities for both parties.