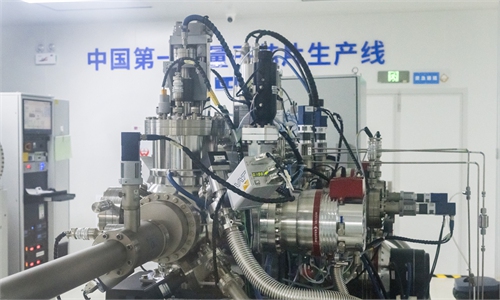

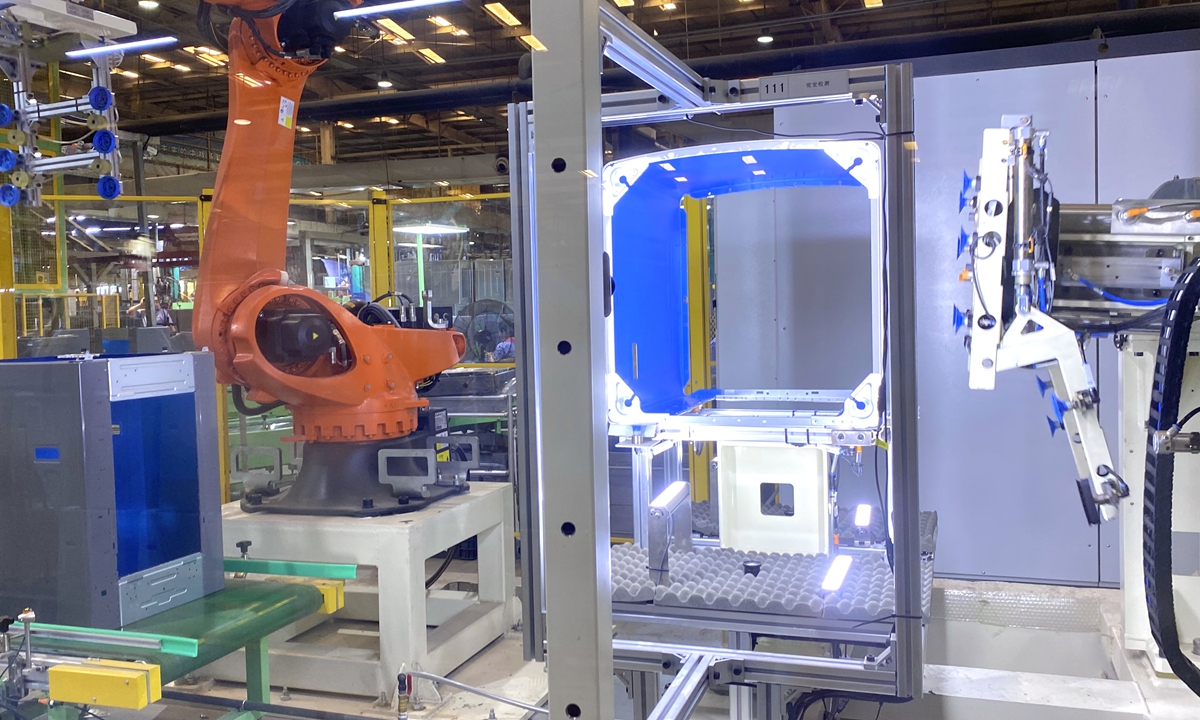

A corner of Hefei Midea Washing Machine Co in Hefei, East China's Anhui Province Photo: Courtesy of Hefei Midea Washing Machine Co

The proportion of "lighthouse factories" from China reached a record high in the new list released by the World Economic Forum (WEF) on Tuesday, highlighting the continuous efforts of Chinese companies to accelerate technology upgrading in the manufacturing sector.

Lighthouse factories are known as "the most advanced factories in the world". McKinsey defines them as factories that have successfully transitioned Fourth Industrial Revolution (4IR) technology from the pilot stage to large-scale integration, achieving significant financial and operational benefits.

Chinese experts said that the rising number of Chinese firms on the list has a solid connection with the foundation of China's manufacturing, and the continuous support of policies is helping lift the nation's manufacturing ability.

The WEF announced that 22 innovative manufacturers have joined the Global Lighthouse Network, including the latest cohort of 19 4IR and three Sustainability Lighthouses across 10 countries, including China and Germany.

Of the total, 13 factories are located in China, accounting for nearly 60 percent, a record high.

Among the 19 new lighthouse factories this year, Mengniu Dairy (Ningxia) Co, SANY Renewable Energy (Shaoshan), Sanmen Nuclear Power Co, Zhengzhou Coal Mining Machinery (Group) Co and Taiyuan Heavy Industry Railway Transit Equipment Co are the world's first lighthouse factories in their respective sectors - dairy, wind energy equipment, nuclear power, coal mining machinery and rail transit equipment.

The increase in the number of lighthouse factories in China is inseparable from the size of China's manufacturing industry, Jiao Xinwang, director of the China Manufacturing Think Tank, told the Global Times.

China has retained its position as the world's top manufacturing hub for 14 consecutive years, and the proportion of China's manufacturing output worldwide rose from 22.5 percent in 2012 to nearly 30 percent in 2021.

Such a base, together with support policies such as those of the Ministry of Industry and Information Technology, show there will be an accelerated push for small and medium-sized enterprises (SMEs) to migrate to the cloud, adopt digital tools and leverage intelligent technologies, which are believed to further foster distinctive industrial clusters of SMEs, experts said.

China's continued implementation of the strengthening plans have greatly improved the modernization of enterprises, narrowing the technology gap between China and other manufacturing powerhouses such as Germany, Japan and the US, Jiao added.

Digital technologies such as generative artificial intelligence (AI) and machine learning are key features of this batch of "lighthouse factories."

Information from the listed Hefei Midea Washing Machine Co shared with Global Times showed that it has continued to explore and reconstruct new end-to-end green and sustainable capabilities, and has extensively deployed digital technologies to apply AI in the product design, manufacturing and broad logistics sectors.

Karel Eloot, a global senior partner at McKinsey, said that the "lighthouse factories" have surpassed the pilot stage, and nearly 60 percent of core application cases use advanced AI technology, compared with just 11 percent in 2019. This shows that AI is reshaping manufacturing and has reached an unprecedented level of maturity.

Since the first selection in 2018, a total of 172 "lighthouse factories" have been designated around the world, with 74 located in China, representing 43 percent.

The Global Lighthouse Network is a global initiative created by the WEF and McKinsey in 2018. It has since released 12 lists of "lighthouse factories."