SOURCE / PRESS RELEASE

First application of intelligent centralized tensioning equipment for live crossing in Xinjiang's Bortala

Photo: State Grid Bortala Power Supply Company

On October 21, a significant milestone was achieved in Bortala, Northwest China’s Xinjiang Uygur Autonomous Region, with the successful live crossing of the 110 kV Bonong Line by the 220 kV outgoing line from the Xinhua Bole South Collection Station. This operation marked the inaugural use of intelligent centralized tensioning equipment for live crossing work in the region.

The construction utilized advanced intelligent centralized visual tensioning equipment, enabling remote control of wire laying. Additionally, mobile crossing frames were employed for network enclosure, and drones were deployed to assist in the installation of guide ropes for the live crossing. This innovative approach signifies a transformative shift towards intelligence and digitization in the mechanized construction practices of the State Grid Bortala Power Supply Company.

The intelligent centralized tensioning equipment is a sophisticated, digital device that allows a single operator to control multiple machines simultaneously. It offers numerous advantages, including comprehensive monitoring and digital display of key parameters throughout the process. In contrast to traditional grid construction methods, which relied heavily on manual labor and mechanical assistance, this new technology significantly reduces the workforce required and minimizes the risks associated with electric shock and mechanical injuries.

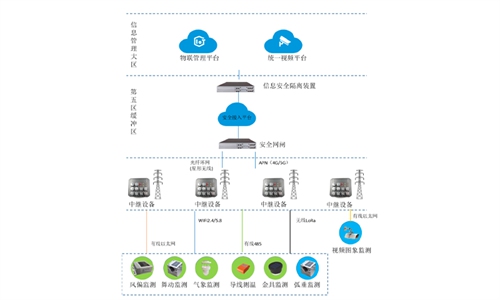

By enabling the "de-coupling of personnel and machinery with remote monitoring," the intelligent centralized visual tensioning equipment allows for the remote oversight of the tugger, tensioning machine, various tower positions, key control points, and wire-laying data. This modern approach reduces manpower requirements by 50 percent compared to conventional wire-laying operations, effectively lowering labor intensity and operational risks.

The 110 kV Bonong Line serves as a vital power supply link between military and civilian sectors. The construction faced considerable challenges and high-risk levels. To mitigate network risks and ensure construction safety, the company independently designed the crossing section during the engineering phase, adopting the "endurance-vertical-endurance" crossing method, which significantly reduced the workload.

During the construction phase, a comprehensive plan was formulated, incorporating four measures and one scheme for the crossing. This included the use of two sets of crossing frames for network enclosure, drones for deploying guide ropes, and intelligent centralized visual tensioning machines for remote wire laying. A thorough review of the construction environment and operational processes was conducted to ensure strict on-site safety management, facilitating the efficient completion of the crossing work.

The 220 kV outgoing project from the Xinhua Bole South Collection Station primarily aims to meet the grid connection and power generation needs of the 100,000 kW thermal energy storage solar project in Bortala, which is part of a larger 900,000 kW renewable energy initiative. Upon completion, this project will further advance the development and construction of renewable energy in the Bortala region, adjust the regional power structure, and complement other local power sources, providing a robust foundation for reducing coal consumption and enhancing environmental benefits.

The company is poised to leverage this opportunity to trial new equipment, continuously enhancing innovative exploration in mechanized construction. By improving construction efficiency and reducing operational safety risks, they aim to drive breakthroughs in grid construction technology and foster a new landscape for the transformation of Bortala's power grid.