Illustration: Xia Qing/GT

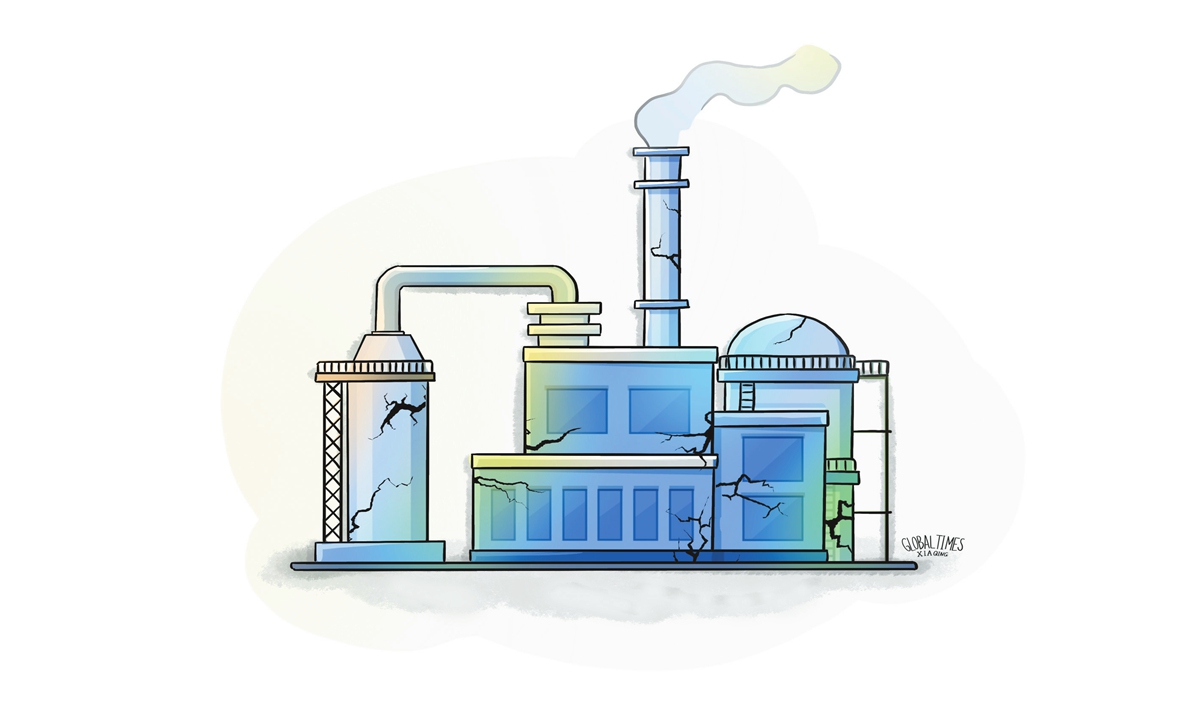

Factory workers at Boeing voted to accept a contract offer that includes a 38 percent wage increase over four years, as well as ratification and productivity bonuses, ending their strike after 53 days, the Associated Press reported.While a deal has been reached to end the Boeing strike, concerns about the stability of the US labor supply and declining consumer confidence remain. The challenges facing US manufacturing persist, as political interference in the supply chain and additional protectionist tariffs are unlikely to strengthen the sector.

Around 30,000 employees of Boeing in the US began a strike on September 13, marking the first strike at the company in 16 years. This strike has affected both upstream and downstream industries, further burdening the US manufacturing sector.

Affected by the Boeing strike, US manufacturing activity slumped to a 15-month low in October. Institute for Supply Management data showed that its manufacturing purchasing managers' index (PMI) fell to 46.5 last month, the lowest level since July 2023, from 47.2 in September. October marked the seventh consecutive month that the PMI remained below the 50 threshold, according to Reuters.

Apart from the aviation industry, key sectors in the US such as vehicles, ports and logistics have experienced a continuous wave of strikes over the past year. These events expose the shortages in the US labor market and profoundly reflect the difficult situation faced by American manufacturing under lingering inflationary pressures.

The US added just 12,000 jobs in October. Earlier, economists had expected the impacts from Hurricane Helene, Hurricane Milton and the strike by Boeing workers to reduce job growth numbers in October. But the number of jobs created was far lower than their estimate of 120,000 jobs for the month, according to the Guardian.

Finding enough skilled workers is expected to be a major obstacle for companies in the manufacturing sector in the US in the future. It's projected that by 2033, an estimated 1.9 million manufacturing jobs could be vacant, according to an article assessing the challenges that the US manufacturing sector confronts by industrial information website Supplychainbrain.com.

The shadow of inflation in the US also lingers. The US Bureau of Economic Analysis reported on October 31 that the core Personal Consumption Expenditures Price Index, which excludes the more volatile food and energy categories, rose by 2.7 percent year-on-year in September, marking the largest monthly gain since April.

In-depth analysis indicates that the causes of inflation in the US are multifaceted, with Washington's political interference in the supply chain and increased tariffs being crucial factors.

Frequent adjustments in US trade policies, export controls on essential raw materials and technologies, and economic sanctions imposed on other countries have all contributed to the instability of global supply chains.

These politically driven actions have not only heightened costs in the US manufacturing sector but also increased the risks of supply chain disruptions.

The most important issue facing American manufacturing is how to address its own problems including labor shortages, less reliable support from surrounding infrastructure and utilities, climate change risks and extreme weather, and supply chain disruptions. The key lies in the US addressing the real domestic challenges that hinder the recovery of its manufacturing sector.

However, the US has adopted trade policies aimed at protecting domestic industries, including irrational tariff hikes on certain imports. But these approaches will not achieve the desired goals.

Additional protectionist tariffs raise the cost of imported goods, which can lead to higher prices for consumers. This can reduce overall demand for products, negatively affecting manufacturers that rely on consumer spending.

Many US manufacturers depend on global supply chains for raw materials and components. Tariff hikes can also disrupt these supply chains, leading to delays, increased costs and inefficiencies that can harm domestic production.

The author is a reporter with the Global Times. bizopinion@globaltimes.com.cn