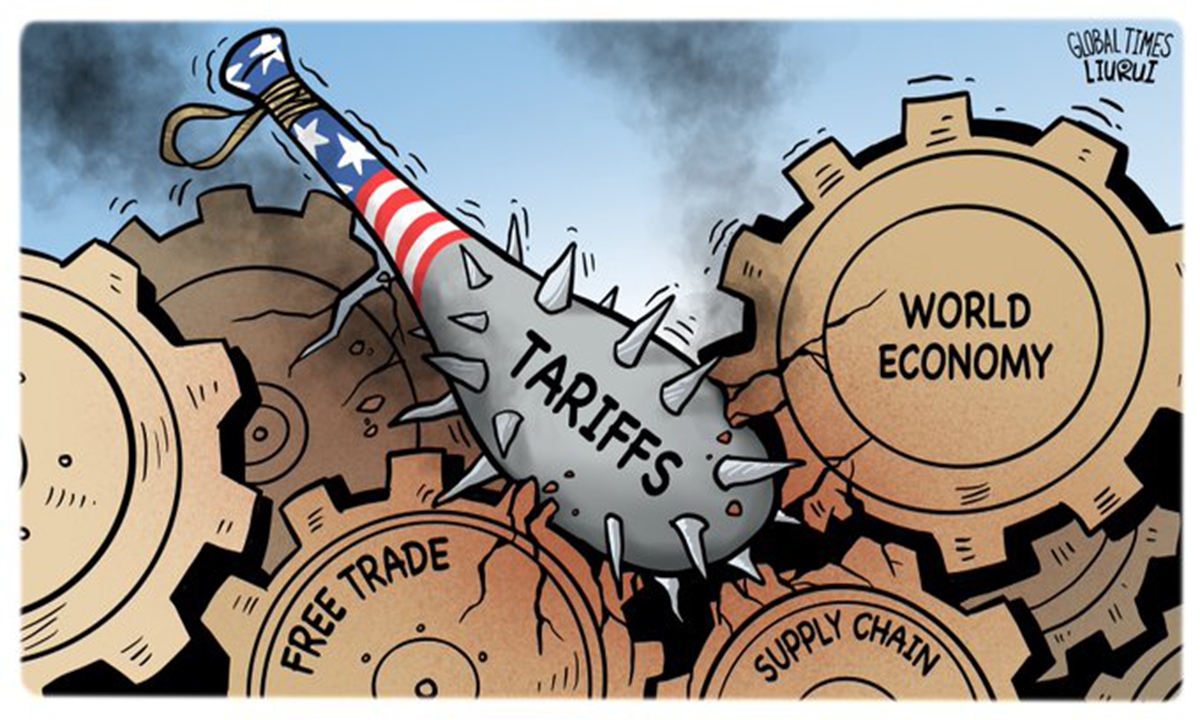

Illustration: Chen Xia/GT

The impending US tariff policy is causing considerable upheaval within the global vehicle industry, raising alarms among stakeholders about its potential ramifications for the entire auto supply chain.However, even against the backdrop of the volatile trade environment, certain indispensable links and key components remain essential to the industry's development, notably those sourced from China, which continue to play a pivotal role in maintaining the efficiency and competitiveness of auto manufacturing.

International carmakers are rushing to ship vehicles and core components to the US to get ahead of the next round of Washington's tariffs, the Financial Times reported on Sunday.

Apparently, fearing the potential chaos that the tariffs, which will come into effect on April 2, could inflict on automotive supply chains, international carmakers are scrambling to ship inventory to the US, a move that could severely strain global supply chains.

Last year, the US imported $471 billion worth of vehicle products. That included $214 billion worth of cars, $192 billion worth of parts and $65 billion worth of trucks, buses and special purpose vehicles.

While it remains unclear the exact tariffs the US will impose on each country, the deeply entrenched networks of global automotive supply chains cannot be unwound overnight. The development so far indicates that the US market and the US auto industry still have high dependence on external supply chains, and the tariffs won't change the fact that they still need to import.

Despite the US government's attempts to promote the reshoring of manufacturing and boost domestic production through policies, the production of many critical components, especially those for next-generation vehicles, cannot be easily transferred back to the US in the short term. The complex and globalized auto supply chain system that the US has long established determines its diverse demand for parts. For new-energy vehicles (NEVs) in particular, the US has a growing need for imported parts due to its shortcomings in key technologies and production links.

S&P Global Mobility warned in a March 12 report that with tariffs imposed on Canada and Mexico, it expects significant disruption in the region, with the potential for North American production to drop by up 20,000 units per day within a week.

For China, the direct impact of the tariff on vehicle exports to the US is limited. China's auto exports to the US accounted for about 2 percent of the country's total auto exports or just 0.4 percent of the auto sales in 2024, according to S&P Global Mobility data.

More importantly, China has made remarkable progress in the auto parts field, especially in NEVs and some core technologies. The production capacity of certain key parts has become an irreplaceable part of the global supply chain. For instance, the US is China's largest export market for auto components, accounting for about 15-20 percent - by value - of such exports in recent years, according to S&P Global Mobility data.

China's auto parts industry has formed a complete system, supported by a large-scale manufacturing base and continuous innovation. Take power batteries as an example. Chinese power battery companies not only account for a large share of global production capacity but also have rich achievements in technological innovation. The continuous iteration and upgrading of lithium-iron-phosphate battery technology, with increasing energy density and decreasing costs, have made Chinese-made power batteries highly competitive in the global market.

Also, in the field of rare-earth materials, China has a complete industrial chain from mining and refining to the research, development and application of related materials, ensuring a stable and high-quality raw material supply for global vehicle parts production.

China also has structural advantages in the fields of electric drive systems and intelligent components, meeting the needs of the global market. This advantage is difficult for the US to replace through localization or "friend-shoring" in the short term.

In conclusion, the US tariffs may temporarily disrupt trade flows, which could ultimately backfire by increasing costs for American automakers and disrupting their normal production and sales processes.