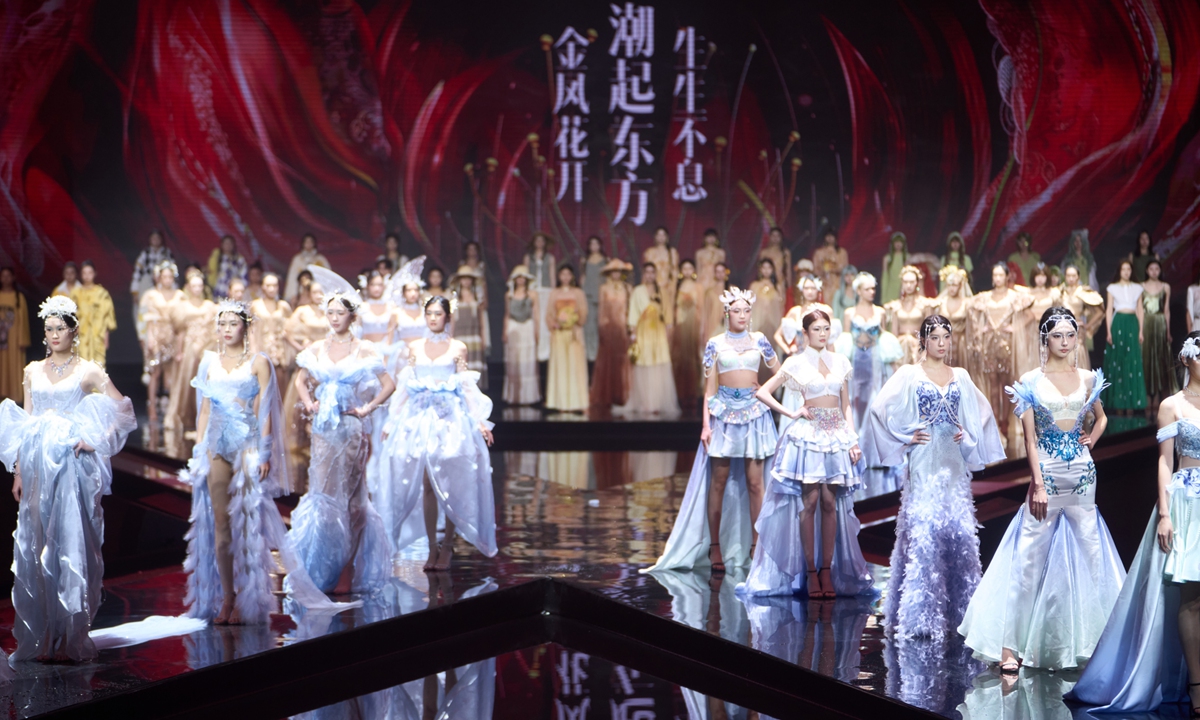

Models showcases the latest fashion collections at the opening ceremony of the 4th China Chaoshan Textile and Garment Exhibition (CTGE), on March 18, 2025. Photo: Courtesy of CTGE

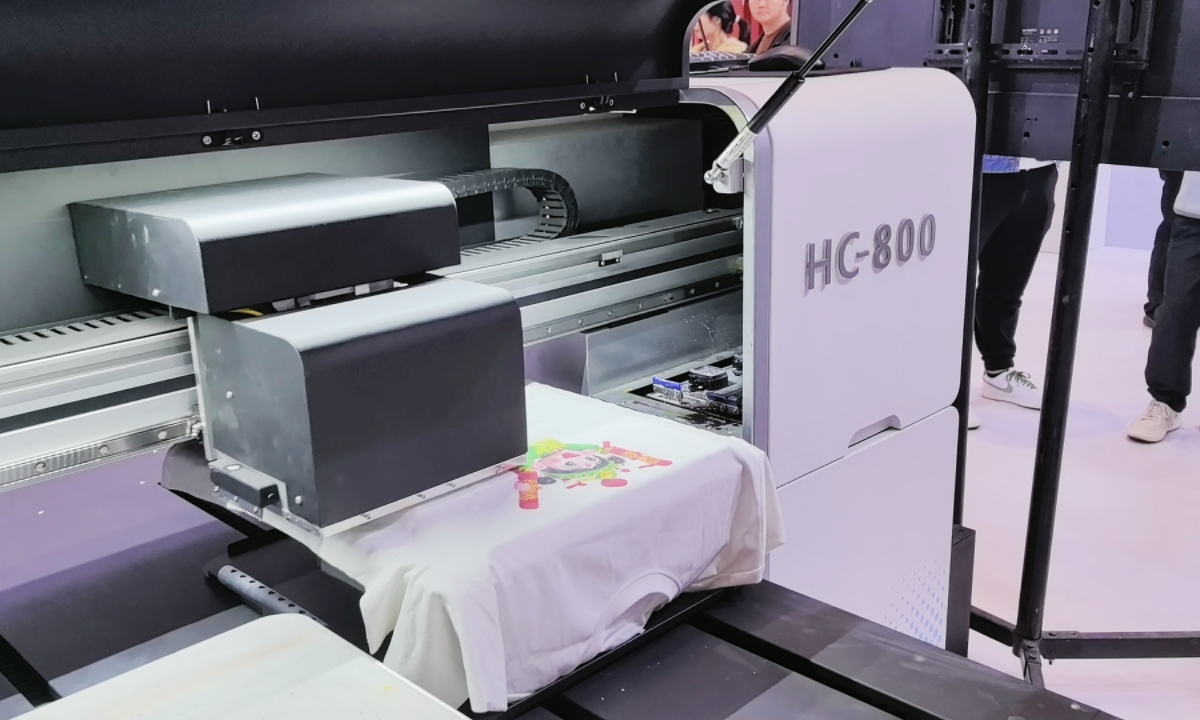

At a booth buzzing with curiosity and camera clicks, visitors type prompts like "red costume," "dancing pose," or "traditional Chaoshan makeup." Powered by DeepSeek, the AI instantly transforms these simple phrases into vivid images of Yingge dancers - the iconic folk performance from the Chaoshan region in South China's Guangdong Province. Moments later, a garment printer springs to life. Within minutes, a custom T-shirt has been printed, dried and is ready for wear.

This interactive setup, part of the 4th Chaoshan Textile & Garment Exhibition held March 18-20 in Shantou, was led by Tang Sipeng's team from China Mobile Guangdong's Shantou branch. It offered a striking fusion of traditional culture and cutting-edge technology. By integrating generative AI with on-demand textile production, the project transforms the heritage of Yingge dance into personalized, wearable art.

Since China's reform and opening-up policy was initiated in the late 1970s, Shantou's textile and garment industry has flourished. But in recent years, traditional textile manufacturing has faced external pressures, spurring a nationwide pivot toward digitalization and advanced tech integration. Shantou stands out as a representative case of this transformation.

Tang's project is just one of many innovations on display at the expo. Advances in textile materials, technological upgrades across industrial and supply chains, and the growing use of AI-powered marketing in cross-border social media platforms have significantly enhanced the global competitiveness of China's textile sector comparable with manufacturers elsewhere. China is set to remain a global leader in textile manufacturing, experts said.

Smart tech transforms manufacturing

Tang told the Global Times that the AI-assisted garment printing technology, powered by DeepSeek, is already commercially viable. "Some of our manufacturing partners have incorporated this process into their actual production lines," he said.

A DeepSeek-powered machine prints personalized T-shirts at the 4th Chaoshan Textile & Garment Exhibition in South China's Guangdong Province on March 18, 2025. Photo: Zhang YIyi/GT

"The system enables on-demand production - design first, sell later," said Tang. "There's zero inventory, as clothes are made only after orders come in." This approach reduces inventory risk while offering a fresh consumer experience, drawing interest from both domestic and international buyers.Other local companies are also embracing advanced technologies to move up the value chain. The Global Times learned that GDKings Co, exhibiting at the expo, has developed two advanced textile technologies that have attracted strong interest from international buyers. Its specialty nylon has a wedge-shaped structure that releases moisture while blocking external water - making it highly breathable and waterproof.

"Used in coatings and concrete, it resists cracking, mold and weathering. With world-class equipment, our company is elevating China's high-end fiber production on the global stage," the merchant told the Global Times.

In addition to upgrading products and processes, companies are turning to smart marketing tools to expand globally. A Shantou government official told the Global Times that the city works with platforms like Chinese social media Douyin and shopping platform Tmall to boost online sales, with some firms using AI virtual hosts for multilingual livestreams.

Automation boosts efficiency

In recent years, automation on China's textile production lines has seen steady improvement, signifcantly enhancing both product quality and manufacturing efficiency.

Wang Yonglin, who makes lace-cutting machines, said their lasers automatically detect patterns and cut with precision - saving time, labor and materials. He noted that as their cutting technology becomes more advanced and increasingly cost-effective, inquiries from foreign buyers, especially from the Middle East and Southeast Asia, have been rising.

An employee uses a lace-cutting machine to automatically detect lace patterns and conduct precision cutting at the 4th Chaoshan Textile & Garment Exhibition in South China's Guangdong Province on March 18, 2025. Photo: Zhang YIyi/GT

"Our ultrasonic machine bonds underwear in just 15 seconds - three times faster than stitching," said Lin, head of De Mo Machinery. "It trims, embosses, and switches styles automatically, saving over 30 percent in energy. We've received lots of orders from Southeast Asia and Europe recently."Higher automation on production lines is attracting strong interest from international buyers. An importer from RJ International told the Global Times he came from India for the advanced technology and competitive pricing. Australian buyer Budisa Stephen Francis echoed the view, praising Shantou's complete textile supply chain, cutting-edge equipment and wide price range.

Industry experts say these trends reflect a wider upgrade. "China's textile industry is now shifting toward the mid-to-high end of the market. Developing high-end fabrics and dyeing technologies is a necessary path for the industry's future," said Xu Jianhua, an official from China Commercial Circulation Association of Textile and Apparel.

Official data shows that Shantou exported $1.23 billion worth of textile products in 2024, underscoring its growing global footprint. Total investment in Shantou's textile sector hit 21.32 billion yuan ($3.05 billion) in 2024 - 31.3 percent of the city's industrial investment and a 35.7 percent year-on-year jump.

From January to December 2024, China's textile and apparel exports totaled $301.1 billion, up 2.8 percent year-on-year. Exports of textiles reached $141.96 billion, marking a 5.7 percent increase, while apparel exports stood at $159.14 billion, up 0.3 percent, according to the China National Garment Association.